A simple wing jig...

Sun Aug 16, 2009 12:47 am

Hey StuMac, Whatta ya think,...Should only take a week or 2 right...

http://warbirdinformationexchange.org/phpBB2/viewtopic.php?t=31352

Chuck

http://warbirdinformationexchange.org/phpBB2/viewtopic.php?t=31352

Chuck

Sun Aug 16, 2009 1:34 am

I don't see what the cry of bloody murder is about. A jig is a straightforward practical support to keep a wing supported correctly during construction, and use basic construction techniques like welding supports and a crossbrace.

Jigs aren't complex at all. I suppose if you're a rocket scientist(Or Prima Donna), you would have to hire a structural engineer to design one, a civil engineer and survey crew to make sure the ground is flat, and an architect to make sure it is estheticly correct. You might even need to cad plate the whole thing to make sure it looks pretty in the hanger, and you can put manufacturer's stamps on it, and wire it up with strobe lights; then yes it would be a very advanced project.

(Let's not forget hydraulic lifting boosting and robotic action as well)

Jigs aren't complex at all. I suppose if you're a rocket scientist(Or Prima Donna), you would have to hire a structural engineer to design one, a civil engineer and survey crew to make sure the ground is flat, and an architect to make sure it is estheticly correct. You might even need to cad plate the whole thing to make sure it looks pretty in the hanger, and you can put manufacturer's stamps on it, and wire it up with strobe lights; then yes it would be a very advanced project.

(Let's not forget hydraulic lifting boosting and robotic action as well)

Sun Aug 16, 2009 9:27 am

Have to agree with A2C on this one. Having built many a jig for Indy car construction, aircraft wings are just bigger, same concept. Anyone have a photo of the jig in question?

Sun Aug 16, 2009 9:58 am

Sure, except for inconsequential items like washout, design twist, dihedral, incidence and other 'unimportant' things that could cause your one and only test flight to end in a twisting end over end to a firey conclusion.

Years ago @ RSTOL we almost lost an AZTEC on test flight when the cherrymaxed on aileron weight 'bump' came loose (found to be bad glass work) and the wingtip started working like a huge fibreglass spoiler and all the airplane wanted to do was roll to the right.

Car jigs are easy, any misalignment can be 'dialed out' by 'tweeking' the suspension to get the ride correct or resort to the old blue tip wrench to fix that distortion, (but then again there have been more than a few racecars that were evil to drive and some killed a few folks because of unintentional preloads and stresses introduced in while building them) taking that out of your equation will be hard to do @ 1500 feet on your first adventure into the third dimension with that new wing-

Years ago @ RSTOL we almost lost an AZTEC on test flight when the cherrymaxed on aileron weight 'bump' came loose (found to be bad glass work) and the wingtip started working like a huge fibreglass spoiler and all the airplane wanted to do was roll to the right.

Car jigs are easy, any misalignment can be 'dialed out' by 'tweeking' the suspension to get the ride correct or resort to the old blue tip wrench to fix that distortion, (but then again there have been more than a few racecars that were evil to drive and some killed a few folks because of unintentional preloads and stresses introduced in while building them) taking that out of your equation will be hard to do @ 1500 feet on your first adventure into the third dimension with that new wing-

Sun Aug 16, 2009 10:39 am

Agreed, I was making the assumption that the person building the jig was smarter than the tools he was working with.

A jig can be built and built correctly to do the job necessary.

A jig can be built and built correctly to do the job necessary.

Sun Aug 16, 2009 1:27 pm

Building the "fixture" (we quit calling them jigs years ago) is very easy as some of you say. But as The Inspector pointed out, you can't just go out and build a fixture without wing drawings or a good wing to start with.

It would be impossible to do with out at least one of the above.

It would be impossible to do with out at least one of the above.

Sun Aug 16, 2009 2:12 pm

mustanglover wrote:Building the "fixture" (we quit calling them jigs years ago) is very easy as some of you say. But as The Inspector pointed out, you can't just go out and build a fixture without wing drawings or a good wing to start with.

It would be impossible to do with out at least one of the above.

Thus the issue-

If you don't have a complete straight wing to build one off of this task gets quite complex and could result in bad things.

I've seen all the highest quality build work create something which would fly badly. The workmanship was great but the fixture and quality control was bad.

Rich

Sun Aug 16, 2009 3:55 pm

51fixer wrote:mustanglover wrote:Building the "fixture" (we quit calling them jigs years ago) is very easy as some of you say. But as The Inspector pointed out, you can't just go out and build a fixture without wing drawings or a good wing to start with.

It would be impossible to do with out at least one of the above.

Thus the issue-

If you don't have a complete straight wing to build one off of this task gets quite complex and could result in bad things.

I've seen all the highest quality build work create something which would fly badly. The workmanship was great but the fixture and quality control was bad.

Rich

So, how would one restore an extremely rare type in which no drawings or jigs (fixtures) survive. Some examples that come to mind are the Oscars that Herb Tischler / TAF restored to flying condition. I don't believe they had complete wings and/or fixtures to use.

If one wanted to restore something exotic from which no documentation or complete examples exist - like say a Japanese Kate which the Hunt brothers recovered from the Kuriles - would it even be possible? Here is what is left:

Would it be possible to rebuild a wing to flyable shape despite only the center section surviving?

Sun Aug 16, 2009 3:58 pm

It can be done, but it is very complex.

There is enough information on most airplanes to be able to build a replica wing. The internals may not be exactly the same, but it can be done.

Once again, the fixtures created would be VERY difficult to build and get set up.

There is enough information on most airplanes to be able to build a replica wing. The internals may not be exactly the same, but it can be done.

Once again, the fixtures created would be VERY difficult to build and get set up.

Sun Aug 16, 2009 4:04 pm

mustanglover wrote:It can be done, but it is very complex.

There is enough information on most airplanes to be able to build a replica wing. The internals may not be exactly the same, but it can be done.

Once again, the fixtures created would be VERY difficult to build and get set up.

But nothing that cubic dollars can't solve, right?

Sun Aug 16, 2009 5:06 pm

warbird1 wrote:mustanglover wrote:It can be done, but it is very complex.

There is enough information on most airplanes to be able to build a replica wing. The internals may not be exactly the same, but it can be done.

Once again, the fixtures created would be VERY difficult to build and get set up.

But nothing that cubic dollars can't solve, right?

This comes down to being completed as a replica.

The cubic $s is right.

You will end up designing an airfoil, every part that is missing you will end up creating that structure from scratch. You'll need engineering to justify how something needs to be made in terms of strength. If none exsits tou'll have to work of of technical data from any source, original, Allied info, pictures any films.

You'll probably end up using fittings from something convenient, say T-6 rudder and elevator structure and make your own ribs to match the shape.

In the end it will be a homebuilt. You will do test flights and maybe end up with a good flying machine.

It will be a gigantic endeavor. and very expensive and time consuming. It will also depend upon your skills and those who are your friends. Having to hire in everything greatly increases costs and adds time.

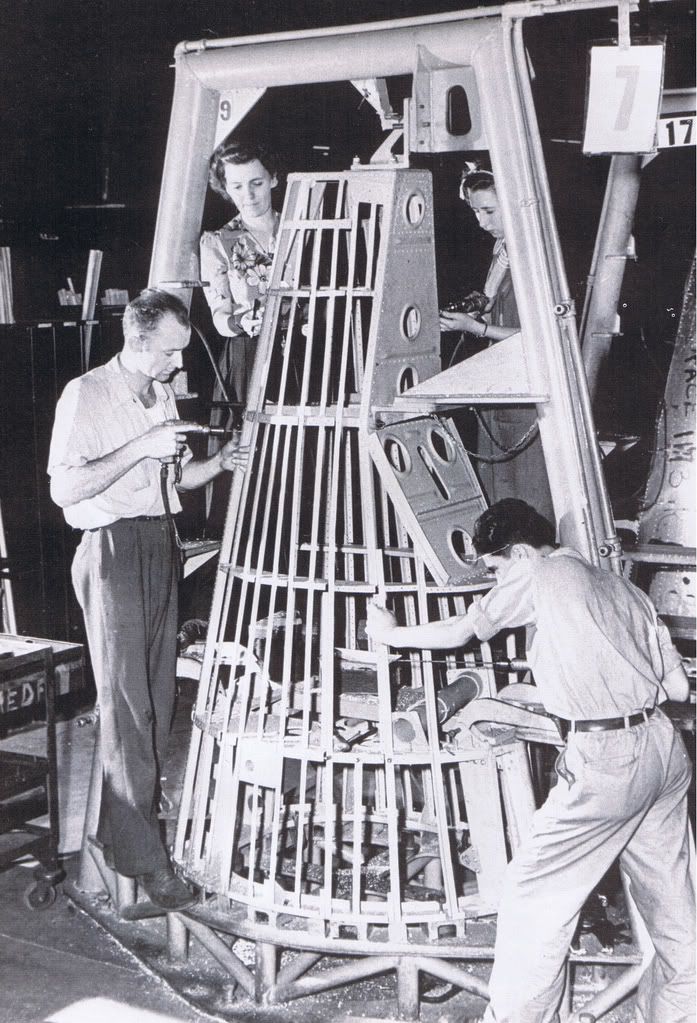

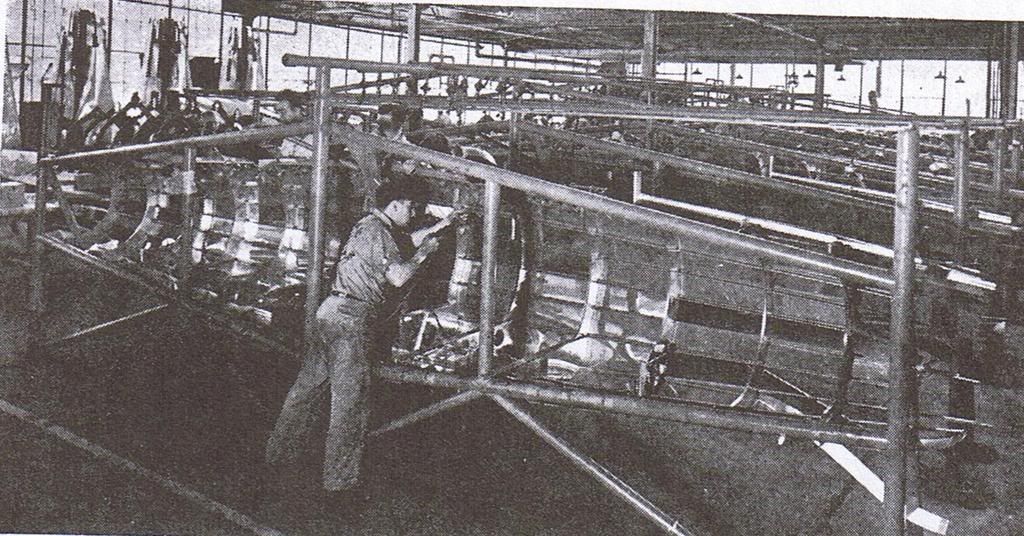

As far as the fixture, here is one a made for a P-51 horizontal. I used a complete, straight one.

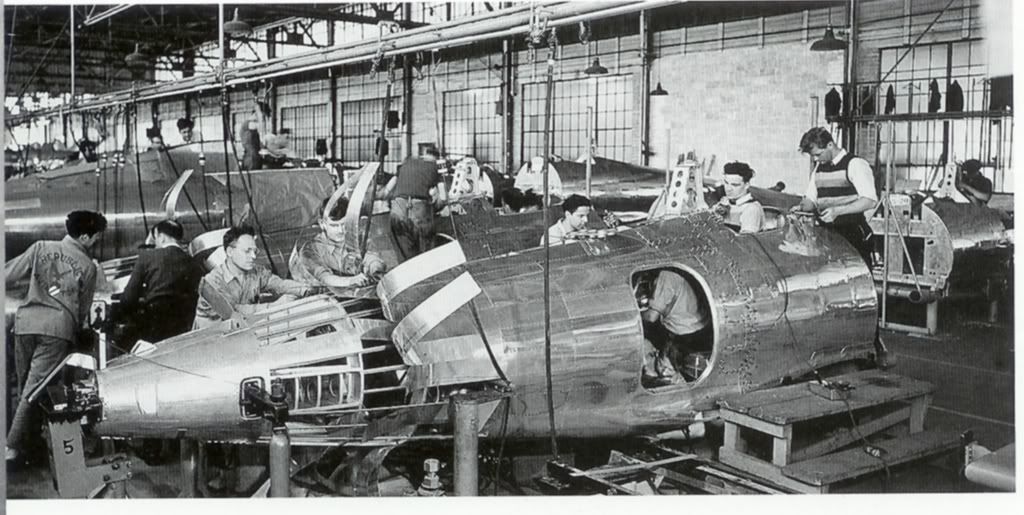

This is one for a P-51 wing. Built by Square One and now owned by Aero Trader.

There is a book I have on aircraft production. I'll try to remember and post the title. It is full of photos from factories.

Rich

Sun Aug 16, 2009 5:09 pm

51fixer wrote:There is a book I have on aircraft production. I'll try to remember and post the title. It is full of photos from factories.

Rich

That would be an interesting book to see.

Gary

Sun Aug 16, 2009 6:41 pm

51fixer wrote:warbird1 wrote:mustanglover wrote:It can be done, but it is very complex.

There is enough information on most airplanes to be able to build a replica wing. The internals may not be exactly the same, but it can be done.

Once again, the fixtures created would be VERY difficult to build and get set up.

But nothing that cubic dollars can't solve, right?

This comes down to being completed as a replica.

The cubic $s is right.

You will end up designing an airfoil, every part that is missing you will end up creating that structure from scratch. You'll need engineering to justify how something needs to be made in terms of strength. If none exsits tou'll have to work of of technical data from any source, original, Allied info, pictures any films.

You'll probably end up using fittings from something convenient, say T-6 rudder and elevator structure and make your own ribs to match the shape.

In the end it will be a homebuilt. You will do test flights and maybe end up with a good flying machine.

It will be a gigantic endeavor. and very expensive and time consuming. It will also depend upon your skills and those who are your friends. Having to hire in everything greatly increases costs and adds time.

As far as the fixture, here is one a made for a P-51 horizontal. I used a complete, straight one.

http://i229.photobucket.com/albums/ee49 ... P_4506.jpg[/img]

This is one for a P-51 wing. Built by Square One and now owned by Aero Trader.

http://i229.photobucket.com/albums/ee49 ... C-869S.jpg[/img]

There is a book I have on aircraft production. I'll try to remember and post the title. It is full of photos from factories.

Rich

That is what I meant to say Rich

Cept I am more quiet sometimes.

Sun Aug 16, 2009 7:39 pm

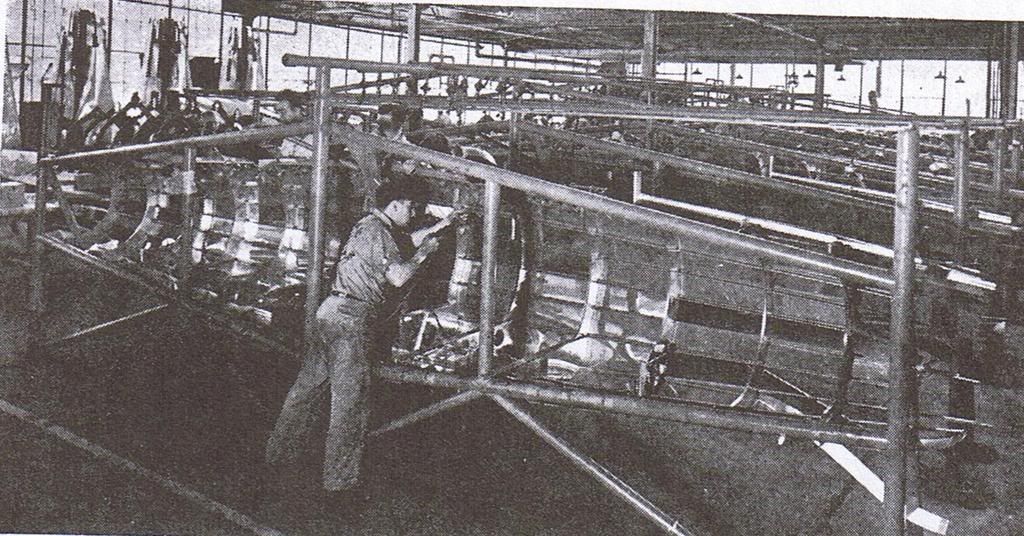

I can relate to the difficulty of building a jig for an aircraft with limited data. Many of the drawings for the P-35 series are basically unreadable and no spare parts or wrecks are available for teardown & study. All existing airframes are assembled and thus limited data can be gained. However other rebuilders have done it and here are some examples:

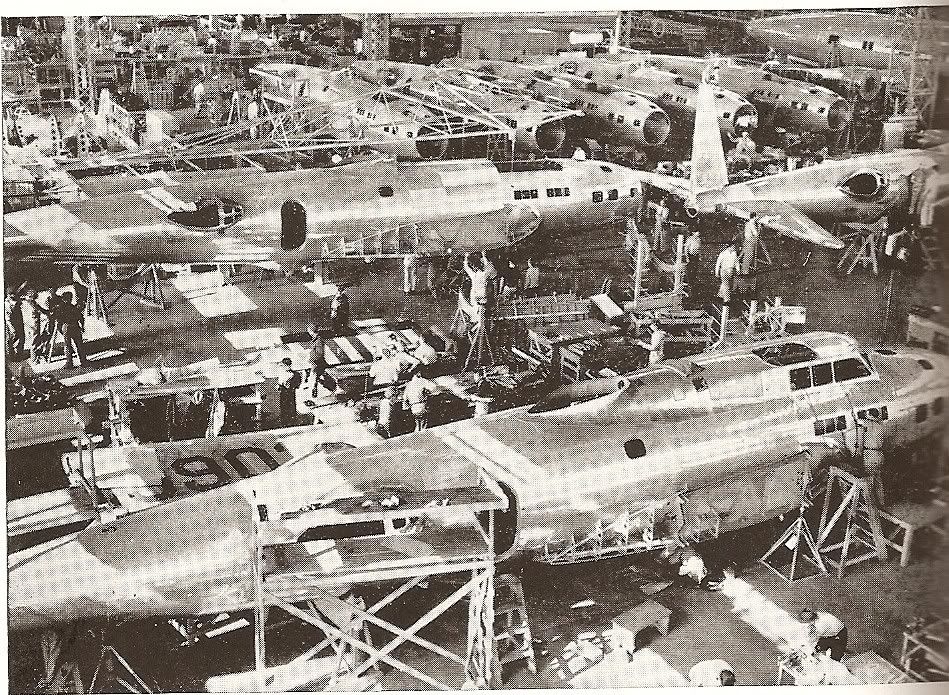

Here a are some P-51 jigs from Fighter Rebuilders at Chino:

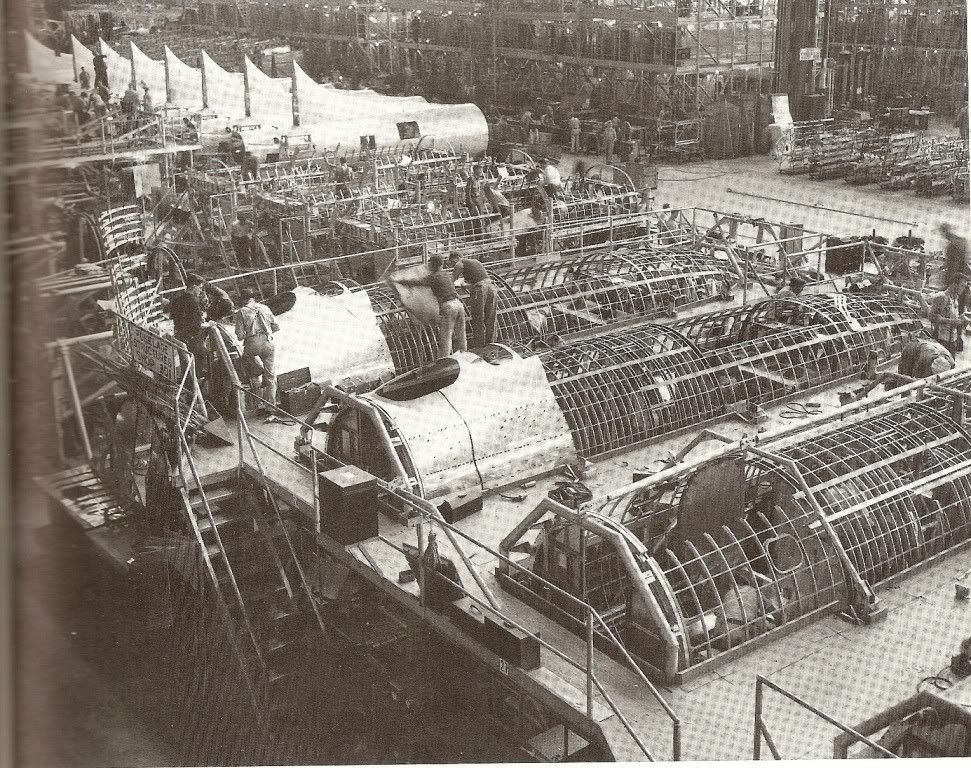

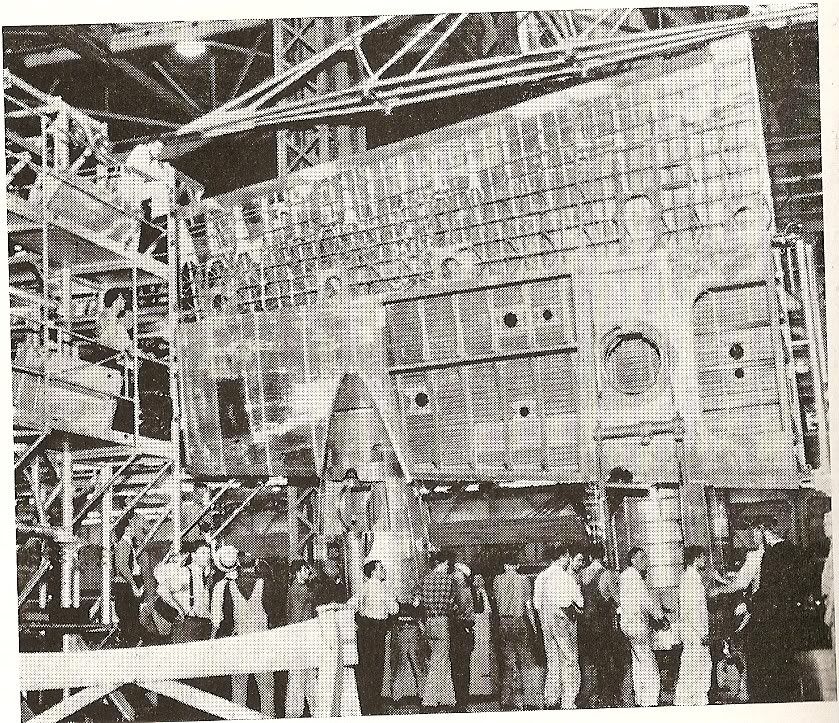

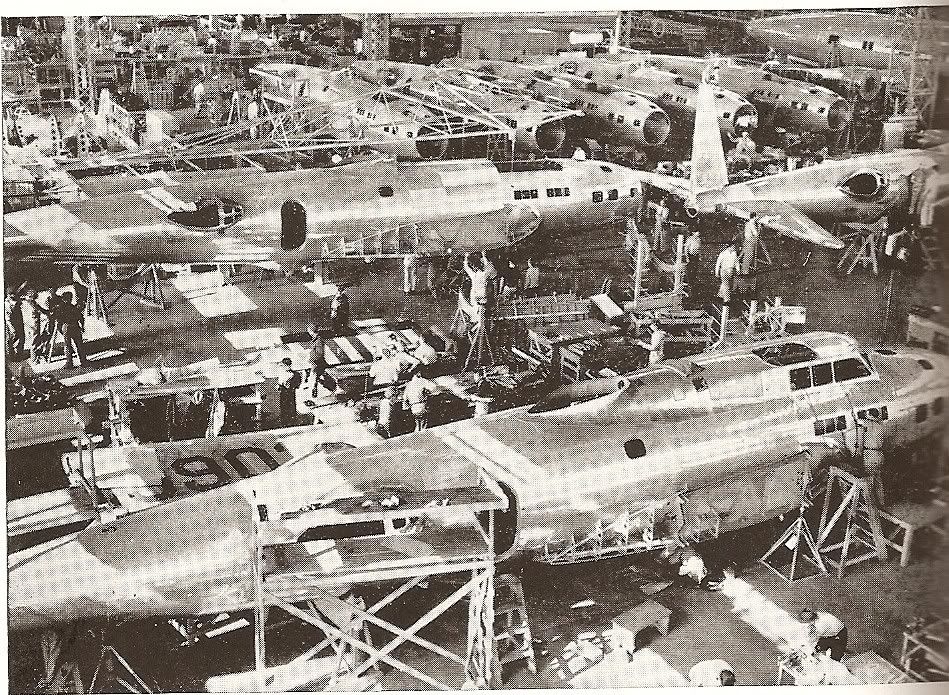

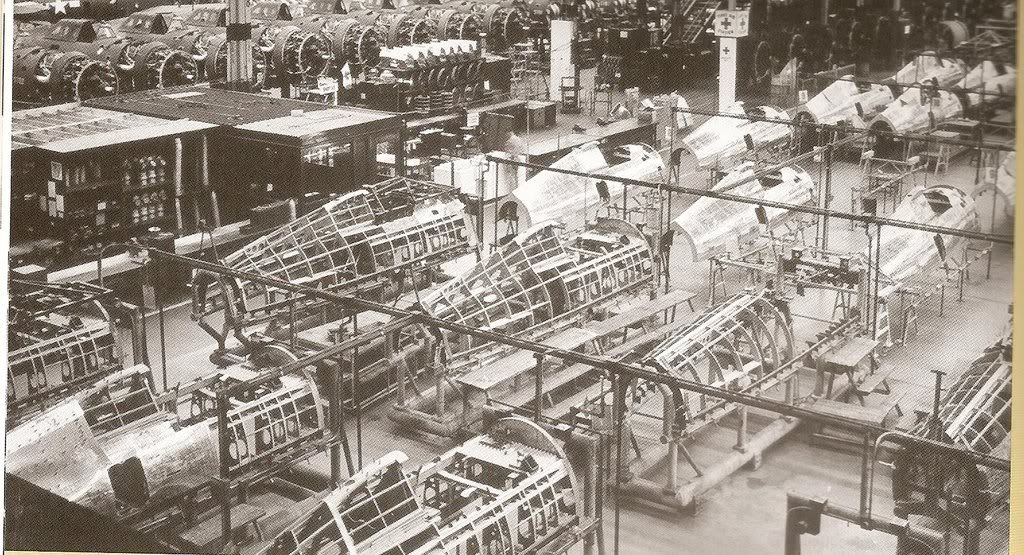

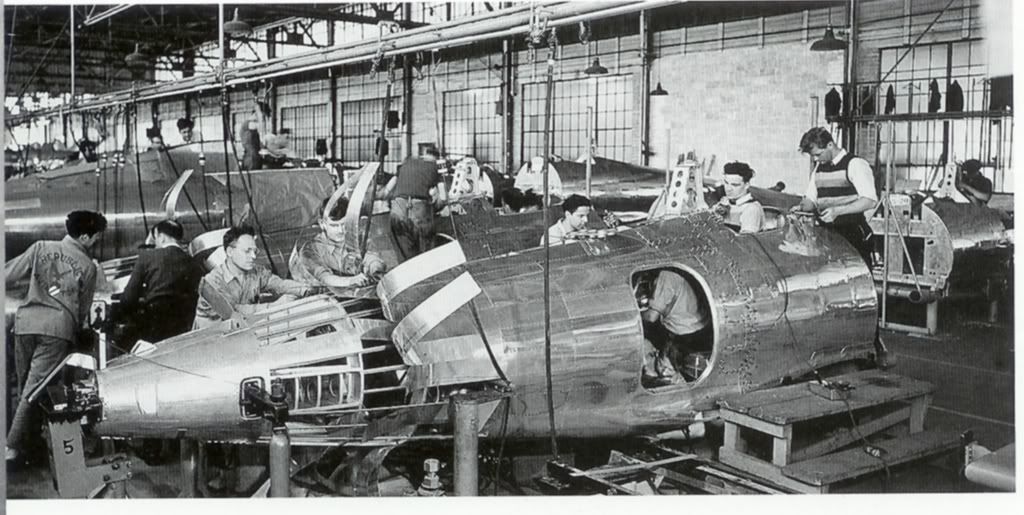

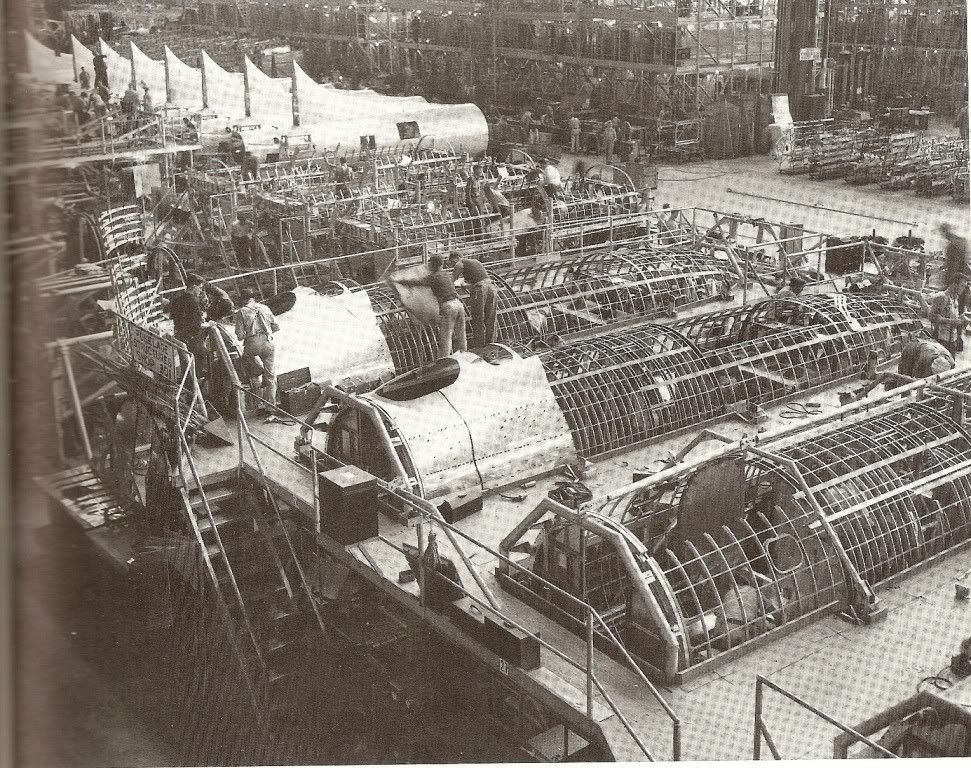

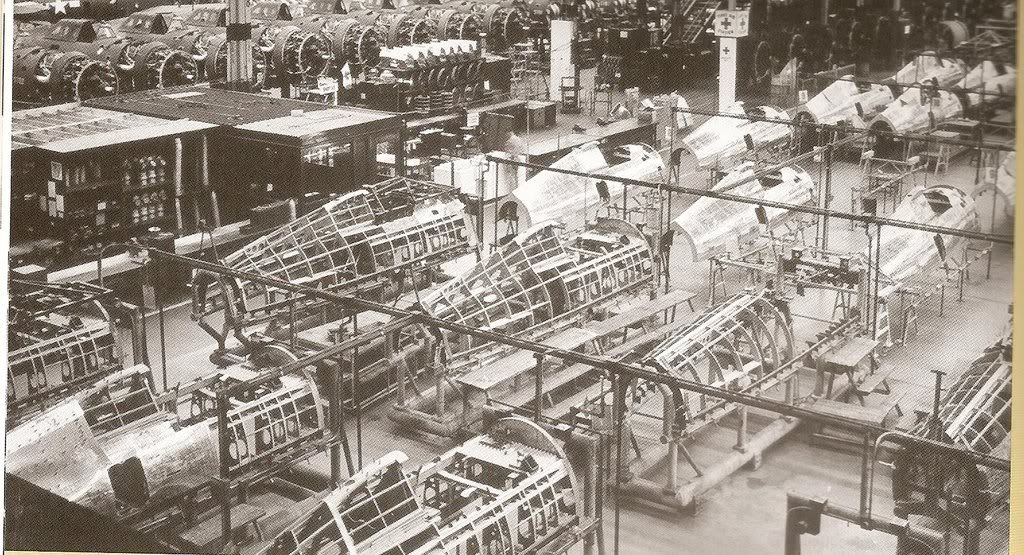

Here are some "vintage" shots from Boeing of B-17 jigs:

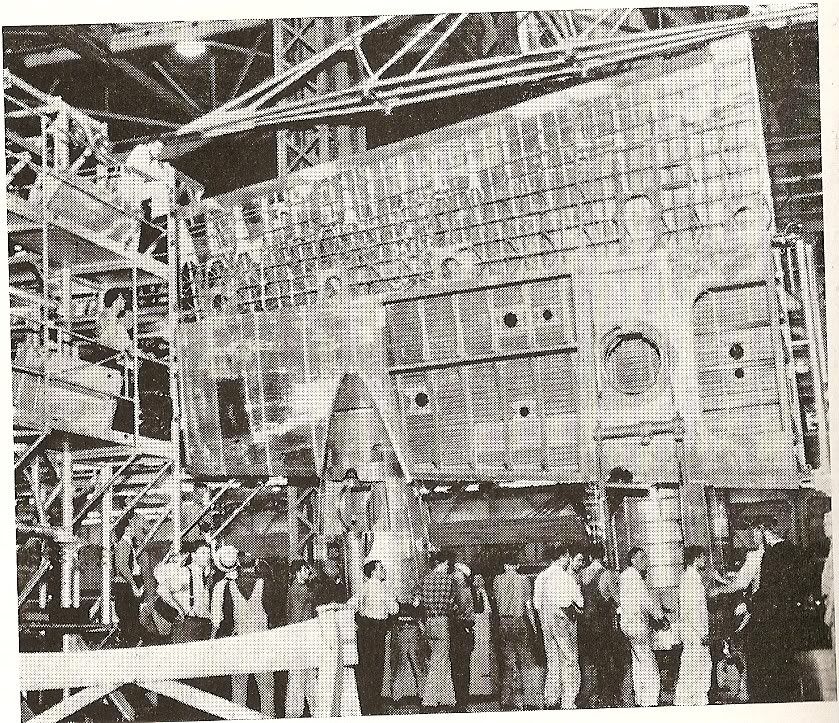

And here is a "modern" shot of a B-17 in a jig (Liberty Belle)

Finally here are some Republic P-47 shots:

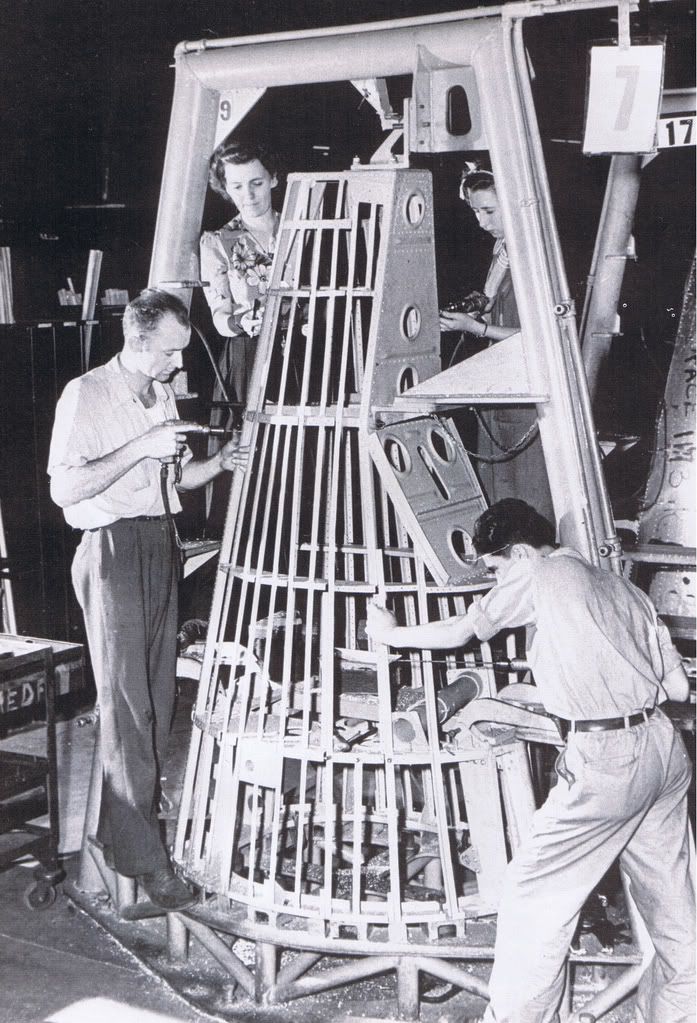

Here is my favorite, the rear fuselage and entire fuselage of a Seversky P-35 under construction in a factory jig (both of which I hope to copy for my replica new build)

Here is my start, it not intended as an assembly jig, but rather a "proof of concept" to determine the best way to construct a proper jig for my P-35A replica project:

Here a are some P-51 jigs from Fighter Rebuilders at Chino:

Here are some "vintage" shots from Boeing of B-17 jigs:

And here is a "modern" shot of a B-17 in a jig (Liberty Belle)

Finally here are some Republic P-47 shots:

Here is my favorite, the rear fuselage and entire fuselage of a Seversky P-35 under construction in a factory jig (both of which I hope to copy for my replica new build)

Here is my start, it not intended as an assembly jig, but rather a "proof of concept" to determine the best way to construct a proper jig for my P-35A replica project:

Sun Aug 16, 2009 9:23 pm

During WWII to speed up construction and deal with a decline in experienced workers aircraft were built in smaller pieces. Such as a left and right side of a fuselage in separate fixtures. Then brought together in a master assembly fixture. The parts were less complicated to make and easier to assemble with less experienced workers building the same high quality product.

Rich

Rich