Hughes XH-17 "Flying Crane"

Mon Mar 30, 2020 2:29 pm

In the wonderful world of butt ugly....It did not fly...Earth just repelled it due to its weirdness....

Yes a Wiki quote....but the info is fun. Man...what a large beast.

Me only wonders what the behavior would have been in case of a main rotor failure!!!! Yikes.

Interesting how the air pressure tip drive reduced the overall torque effect of the rotor....There was a lot more mass on top than normally found in traditional choppers; just quite a different ratio. Hence such a small tail rotor!!!!

https://en.wikipedia.org/wiki/Hughes_XH-17

Hold on Frank!

What a rotor setup

Yes a Wiki quote....but the info is fun. Man...what a large beast.

Me only wonders what the behavior would have been in case of a main rotor failure!!!! Yikes.

Interesting how the air pressure tip drive reduced the overall torque effect of the rotor....There was a lot more mass on top than normally found in traditional choppers; just quite a different ratio. Hence such a small tail rotor!!!!

https://en.wikipedia.org/wiki/Hughes_XH-17

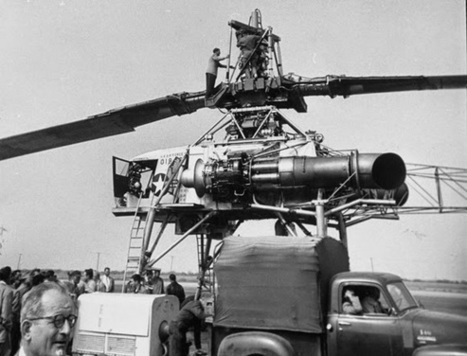

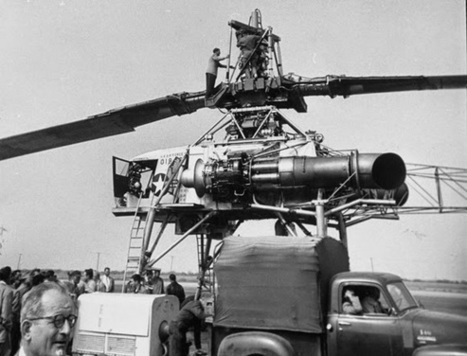

The XH-17 was a heavy-lift rotorcraft that was designed to lift loads in excess of 15 metric tons. To speed construction, parts of the XH-17 were scavenged from other aircraft. The front wheels came from a North American B-25 Mitchell and the rear wheels from a Douglas C-54 Skymaster. The fuel tank was a bomb bay-mounted unit from a Boeing B-29 Superfortress. The cockpit was from a Waco CG-15 military glider and the tail rotor from a Sikorsky H-19 Chickasaw was used for yaw control.

In the late 1940s, Hughes developed an interest in helicopters. In August 1947, helicopter manufacturer Kellett sold his design for the giant XH-17 Sky Crane to Hughes, who commissioned the development of the XH-17 Flying Crane research vehicle. In 1948, the XH-17 began to take shape. The giant helicopter was tested in Culver City, California over a three-year period beginning in 1952. The XH-17 flew in 1953 at a gross weight in excess of 50,000 pounds (23,000 kg). It still holds the record for flying with the world's largest rotor system. Only one unit was built, since the aircraft was too cumbersome and inefficient to warrant further development.

Two cars parked beneath the XH-17 give a sense of scale.

The propulsion system was unusual. Two General Electric J35 turbojet engines were used, sending bleed air up through the rotor hub. The blades were hollow, and the hot compressed air traveled through the blades to tip jets where fuel was injected. In flight, the main rotor spun at a sedate 88 revolutions per minute, less than half the speed of typical helicopter rotors. Since the rotor was driven at the tips rather than the hub, little torque compensation was required, mostly due to friction in the main rotor bearing. Thus, the XH-17 had a very small tail rotor compared to its main rotor. This drive system was inefficient, limiting the test aircraft to a range of only 40 miles (64 km).

Hold on Frank!

What a rotor setup

Re: Hughes XH-17 "Flying Crane"

Mon Mar 30, 2020 4:03 pm

Not ugly but interesting. You could look at it for a long time and not take it all in.

Re: Hughes XH-17 "Flying Crane"

Mon Mar 30, 2020 5:03 pm

Another one of Hughes "Hold my Beer" moments...

Re: Hughes XH-17 "Flying Crane"

Mon Mar 30, 2020 5:05 pm

Kinda looks like they weren't done building it.