No, no paint yet. We thought about a quick paint job but figured it would be a waste of expensive donated paint if we didn't do the proper preparation. Dents and dings as well as lots of fasteners that need to be replaced. Rusty Dzus fasteners is one of the seemingly small projects but is actually pretty big. We can't just clean the rusty heads and paint them because they will rust from the areas you can't get to namely under the heads between the panel and it will start streaking the new paint with rust. The only way to fix this is to remove the fasteners and re-plate them or replace them. Fortunately I bought a good stash of stainless Dzus hardware a few decades ago that are the correct size for the Harpoon. I think there are over 400 of them that will be replaced.

Lots of prep to do before paint so bear with us or better yet come on out and help!

Please remember we all are volunteering on the old gal mostly after hours and on weekends. Heck, Larry was working on her all week without pay when he could have been earning a living just so we could make the air show. Great spirit going into this great old warbird from some great people.

Yes, the locked down tail wheel is butt ugly. We were commenting on that just yesterday as we watched air to air video that my daughter shot over the weekend. It is just one of the many projects we need to do so until we get it to retract send out the tail wheel spat and I will bolt it on in your name.

On to some recent work:

We removed the Andover APU from the rear fuselage and moved the batteries to their original location just aft of the entry door. The Colorado boys fixed up all of the glass frames then Scott and his brother started cleaning up the tunnel gun glass area. Ken finished it up and painted the fuselage frames.

Here is Ken pulling out the wiring that extended to the batteries being placed as far back in the tail as possible. When the military gear was pulled out the Harpoon became nose heavy so the APU, batteries and lead were placed in the back end.

Then the prep and paint

We made the glass (polycarbonate) in the shop for both the flat sides and the curved lower panels. The big S shaped panel was a challenge but turned out great. It took a while to make the tooling but it was worth the effort.

Here is Ken, Larry and Ron installing the new glass

Turned out okay

We found the missing stainless steel cowling that covered the exhaust and Larry installed it. It sure looks good too

Some trinkets go back in place

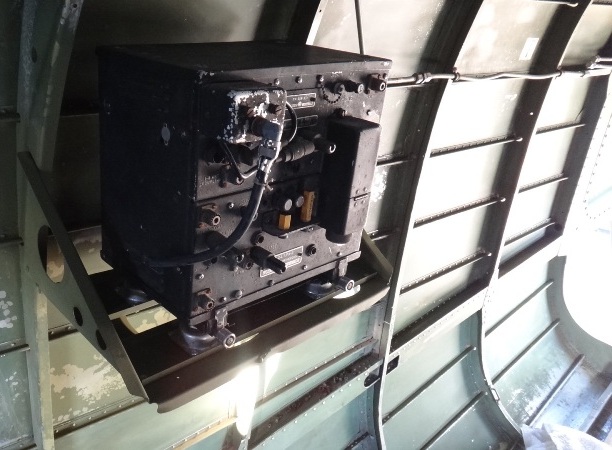

APX-2 IFF set

The receiver/transmitter and shock mount get a good cleaning and then get bolted in place

Impact switch. On crash or impact it fires off the explosive squibs inside the secret IFF (Identification Friend of Foe) so it would not fall into enemy hands. I have heard stories of it going off on hard landings. Glad it isn't working for my landings!

Kenny looks pretty serious about installing the impact switch!

Here is the pilots control box for the IFF mounted overhead in the cockpit. He can destroy the IFF set with a switch too. Interesting that there is an ABA-1 switch decal installed in this late 1945 aircraft as the early ABA-1 IFF was long since obsolete when this Harpoon was built.

The Nav table went back in place all finished

More to follow

_________________

To donate to the PV-2D project via PayPal click here

http://www.twinbeech.com/84062restoration.htmWe brought her from:

to this in 3 months:

Help us get her all the way back

All donations are tax deductible as the Stockton Field Aviation Museum is a 501c3 nonprofit organization. Tell a friend as the Harpoon needs all the help she can get.

Thank you!

Taigh Ramey

Vintage Aircraft, Stockton, California

http://www.twinbeech.com'KEEP ‘EM FLYING…FOR HISTORY!'