Larry Kraus wrote:

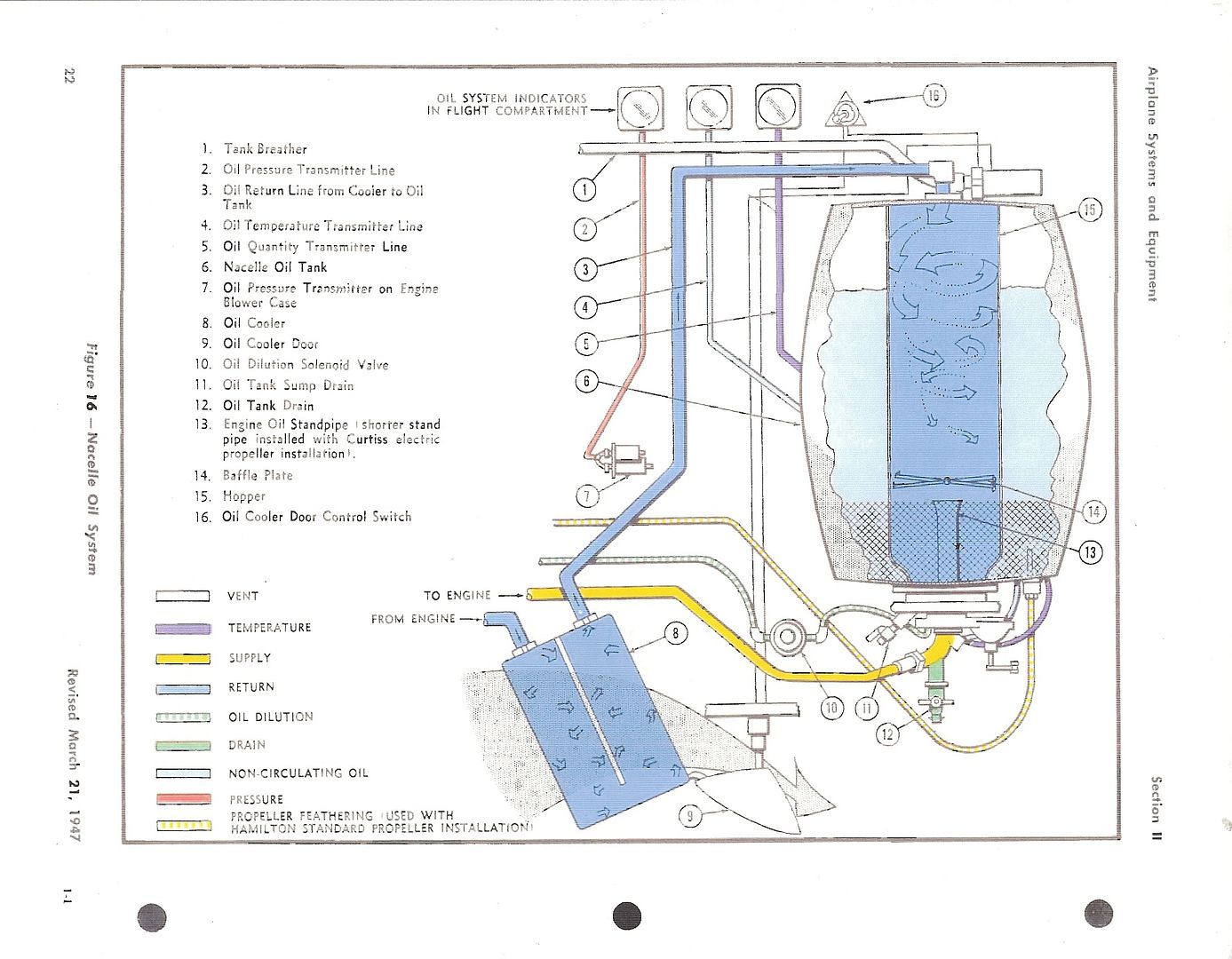

Here's a good depiction of the oil tank on an early DC-6 that shows the standpipe (item 13).The crosshatched oil below the top of the standpipe can only be accessed by running the feather pump.

Larry, I would say that there is a good similarity between this diagram and the B-17 tank fit.

The main difference seems that the feathering pick off point on the diagram shows it in an entirely different place to the B-17 which has both main oil and feathering oil pick off points directly next to each other into the fitting at the bottom of the tank into what the diagram calls a hopper.

Larry Kraus wrote:

Here are pages from a flight manual for a Navy R7V-1 (Connie) concerning the Runaway Propeller Emergency Procedure.

The wording interests me in these manual notes.

It writes about propeller RPM for example as 2900, but my understanding is that the RPM is in fact for the engine and not the propeller as the tachometer giving the RPM indication, is driven by the engine with the propeller turning at many, many less revolutions by comparison.

I can't say what it would be in the this case as I do not know the ratio of the reduction gear fitted to this particular aeroplanes' engines.