Restoration Progress on O-58A 42-7796

Sat Dec 07, 2013 1:02 pm

Home from the paint shop and we are beginning to install Beford cord interior panels, glass, controls etc. This morning I painted on the Squadron tail identification numbers, 7796 was aircraft # 24 assigned to the 109th Observation Squadron. We are replicating the paint and markings the aircraft had the Spring of 1942 with the red meatball center removed from the National Insignia. The yellow radio call numbers were not in effect at this date and time. The Insignia white and blue were custom mixed from my WW II paint color cards. The Insignia White is very off white almost light Ivory.

I used oil board stencils and airbrushed the flat black to achieve the soft edges around the numbers as they would have been painted on in the field at Squadron level.

I used oil board stencils and airbrushed the flat black to achieve the soft edges around the numbers as they would have been painted on in the field at Squadron level.

Re: Restoration Progress on O-58A 42-7796

Sat Dec 07, 2013 5:14 pm

Looking good!

This is gonna be fun!

Andy Scott

This is gonna be fun!

Andy Scott

Re: Restoration Progress on O-58A 42-7796

Sun Dec 08, 2013 9:43 am

It's looking great. IN an earlier post I had recommended upgrading the engine because of the aircraft's marginal performance with the 65hp. Y'all indicated it would be rebuilt with the 65 hp. YOu may want to consider sourcing a used metal prop to put on it at some point in the future.

Second, the design, with power off for landing , drops like a stone with a sink rate around 800 fpm. ( I remember it compares to a Maule M-5 full flaps, idle power.) SO my I suggest, as it begins to get reassembled. to take great care in minimizing drag and try to figure out where all that drag is coming from.

I remember on my friend's L-3A/ O-58, it was as though we had spoilers deployed or a drogue chute attached. It can get into a field and land with about a third of the field length required to take back off. A 65hp J-3 will climb and fly with 2 people aboard and the windows and doors open. The O-58A really struggles to do the same. Actually that is c a close comparison. THe cool thing about the O-58A is it has the tightest turning radius of any aircraft in it's class, including the Cub.

Second, the design, with power off for landing , drops like a stone with a sink rate around 800 fpm. ( I remember it compares to a Maule M-5 full flaps, idle power.) SO my I suggest, as it begins to get reassembled. to take great care in minimizing drag and try to figure out where all that drag is coming from.

I remember on my friend's L-3A/ O-58, it was as though we had spoilers deployed or a drogue chute attached. It can get into a field and land with about a third of the field length required to take back off. A 65hp J-3 will climb and fly with 2 people aboard and the windows and doors open. The O-58A really struggles to do the same. Actually that is c a close comparison. THe cool thing about the O-58A is it has the tightest turning radius of any aircraft in it's class, including the Cub.

Re: Restoration Progress on O-58A 42-7796

Sun Dec 08, 2013 10:50 am

marine air wrote:It's looking great. IN an earlier post I had recommended upgrading the engine because of the aircraft's marginal performance with the 65hp. Y'all indicated it would be rebuilt with the 65 hp. YOu may want to consider sourcing a used metal prop to put on it at some point in the future.

Second, the design, with power off for landing , drops like a stone with a sink rate around 800 fpm. ( I remember it compares to a Maule M-5 full flaps, idle power.) SO my I suggest, as it begins to get reassembled. to take great care in minimizing drag and try to figure out where all that drag is coming from.

I remember on my friend's L-3A/ O-58, it was as though we had spoilers deployed or a drogue chute attached. It can get into a field and land with about a third of the field length required to take back off. A 65hp J-3 will climb and fly with 2 people aboard and the windows and doors open. The O-58A really struggles to do the same. Actually that is c a close comparison. THe cool thing about the O-58A is it has the tightest turning radius of any aircraft in it's class, including the Cub.

No question that a Cub will outperform a L-3 any day of the week. However the O-58A is very different than the L-3B and C. The O-58A is 85 lbs lighter because it has a smaller spruce greenhouse where the L-3B is welded steel tubing and larger, front brakes only and other significant differences.. The two aircraft have different frames with the diagonal tubes running in opposite directions aft of the fuselage There are only two O-58A aircraft left mine and the one owned by Blake Henderson in Tenn that was crashed a couple of years ago. You must have flown Blakes aircraft at some point in time. The one that was reported to be at the Ft. Rucker Museum was a replica and wearing the tail number belonging to Blakes aircraft 42-7798.

Also a lot of 65 hp engines currently flying are not producing anywhere near the original power when new. If you rebuild a 65 hp with a good cam and crank, very good lifter bodies and new cylinders you will be shocked at how powerful these little engines are. By the time you hang an 85 hp engine and add the metal prop, wing tank and sometimes battery and starter you have almost negated the 20 hp difference between the two engines.

You are spot on with your comment about the need to keep the aircraft light during construction. Also I very rarely give rides in my aircraft and the only two people that fly in my planes are myself at 172 lbs and my wife at 110 lbs. 65 hp aircraft have never been a problem for us in the past and have performed well.

Re: Restoration Progress on O-58A 42-7796

Sun Dec 08, 2013 11:06 am

Looks like some great progress on this aircraft! I've always enjoyed looking over authentic L-bird and O-bird restorations. Lots of great craftsmanship here and elsewhere. I'm sure this one will be a head-turner when complete!

Re: Restoration Progress on O-58A 42-7796

Sun Dec 08, 2013 8:07 pm

You guys have done your homework. Good point about the engine, He may have not had a very strong 65 hp. Also, his cowling was original , banged up and loose. I remember several times looking at the aircraft and wondering if there was any way to reduce the drag coefficient. I think the door mounted outside of the frame as opposed to flush like a J-3. He had larger than standard tires on it too.\

Also when purchasing new spars ,there were two types of wood available and he went with the cheaper but heavier wood.

Also when purchasing new spars ,there were two types of wood available and he went with the cheaper but heavier wood.

Re: Restoration Progress on O-58A 42-7796

Wed Dec 11, 2013 2:29 pm

kalamazookid wrote:Looks like some great progress on this aircraft! I've always enjoyed looking over authentic L-bird and O-bird restorations. Lots of great craftsmanship here and elsewhere. I'm sure this one will be a head-turner when complete!

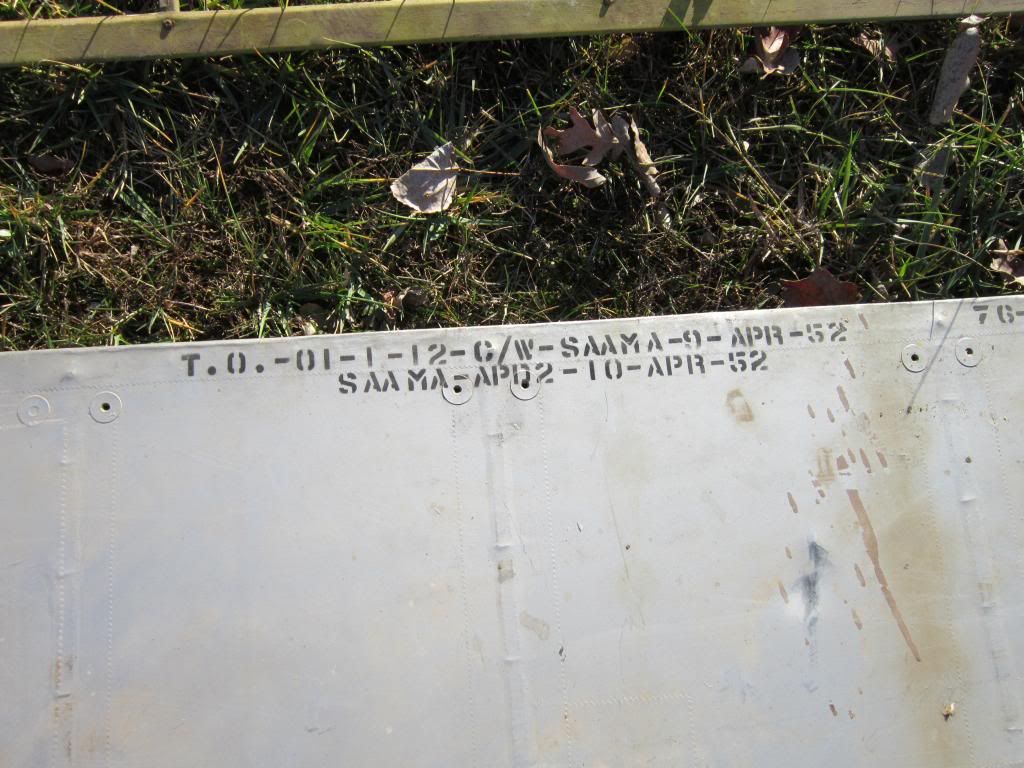

Thanks, it is very time consuming to add all of the little details accurately based on the factory drawings and Army tech orders. This fuselage stencil containing dope and manufacturing data was so long I had to make it in three parts, still have to add date covered and date frame built.

Re: Restoration Progress on O-58A 42-7796

Wed Dec 11, 2013 5:27 pm

Looks great!

Side comment/question for the WIX brain trust: Did these Army TOs requiring cover codes on covered parts expire prior to 42/3? The reason I ask is Stinson did not conform to this standard during L-5 production. The only time I've seen cover codes in photos or on WWII covered parts are depot overhauled parts (particularly ailerons). I would love to see proof to the contrary. Anyone have anything? On my L-5G, I put cover codes on one aileron and purposefully mismatched the camo to replicate a Tokyo Air Material Depot replacement. I've had people tell me I should have them on all covered components, but so far there is no proof via thousands of photos, documents, and factory blueprints. I think cover codes are neat though!

Keep up the great work!

Side comment/question for the WIX brain trust: Did these Army TOs requiring cover codes on covered parts expire prior to 42/3? The reason I ask is Stinson did not conform to this standard during L-5 production. The only time I've seen cover codes in photos or on WWII covered parts are depot overhauled parts (particularly ailerons). I would love to see proof to the contrary. Anyone have anything? On my L-5G, I put cover codes on one aileron and purposefully mismatched the camo to replicate a Tokyo Air Material Depot replacement. I've had people tell me I should have them on all covered components, but so far there is no proof via thousands of photos, documents, and factory blueprints. I think cover codes are neat though!

Keep up the great work!

Re: Restoration Progress on O-58A 42-7796

Wed Dec 11, 2013 9:01 pm

Taylor Stevenson wrote:Looks great!

Side comment/question for the WIX brain trust: Did these Army TOs requiring cover codes on covered parts expire prior to 42/3? The reason I ask is Stinson did not conform to this standard during L-5 production. The only time I've seen cover codes in photos or on WWII covered parts are depot overhauled parts (particularly ailerons). I would love to see proof to the contrary. Anyone have anything? On my L-5G, I put cover codes on one aileron and purposefully mismatched the camo to replicate a Tokyo Air Material Depot replacement. I've had people tell me I should have them on all covered components, but so far there is no proof via thousands of photos, documents, and factory blueprints. I think cover codes are neat though!

Keep up the great work!

Great question Taylor, I have attached the tech order dated June 1942, it is possible the requirement was removed at a later date. I am only placing stencils on the O-58A that are specifically called for on the factory drawings (location, content and format) I will include photo copies of the drawings in my Restoration book I will carry to shows. In every case each stencil will match back to the factory drawing. So far I have not found any drawing that calls for stencils on the stabilizer, elevators or ailerons. There is one stencil on the rudder and one on the bottom of both wings along with the usual boot cowl stencil. My rule is if I cannot document something in the factory drawings it does not go on the aircraft. Have you checked with Jim Gray about obtaining the master factory Drawing for the covered fuselage that might contain the information you are looking for? I am amazed at how much information we have for the Aeroncas compared to the Piper L-4.

Re: Restoration Progress on O-58A 42-7796

Wed Dec 11, 2013 9:11 pm

Re: Restoration Progress on O-58A 42-7796

Wed Dec 11, 2013 9:22 pm

I believe it was on there originally. I'm restoring an old Army jeep and sometimes the original stenciling is extremely thin. Also. if the camera wasn't focused on that area, and it would almost never be , then it simply wouldn't be picked up on film. Last, that is a "high wear" area prone to patching and redoping/ taping if they are operating off of gravel, mud , or anything other than hard asphalt.

Re: Restoration Progress on O-58A 42-7796

Wed Dec 11, 2013 9:25 pm

marine air wrote:I believe it was on there originally. I'm restoring an old Army jeep and sometimes the original stenciling is extremely thin. Also. if the camera wasn't focused on that area, and it would almost never be , then it simply wouldn't be picked up on film. Last, that is a "high wear" area prone to patching and redoping/ taping if they are operating off of gravel, mud , or anything other than hard asphalt.

I agree

Re: Restoration Progress on O-58A 42-7796

Mon Dec 16, 2013 5:18 pm

Re: Restoration Progress on O-58A 42-7796

Mon Dec 16, 2013 9:45 pm

The T-6 Aileron I have for sale has the Depot dope info from (I assume) Kelly.......SAAL San Antonio Air Logistics??

Re: Restoration Progress on O-58A 42-7796

Mon Dec 16, 2013 11:13 pm

L-4Pilot wrote: Great question Taylor.... In every case each stencil will match back to the factory drawing.... My rule is if I cannot document something in the factory drawings it does not go on the aircraft. Have you checked with Jim Gray about obtaining the master factory Drawing for the covered fuselage that might contain the information you are looking for?

Right there with ya, Steve. I have a complete set of L-5 blueprints and there's nothing in there about it. It's just curious that CV-Stinson seemed to ignore the TO. One of those warbird mysteries, I guess.

Interior looks great. Keep it up!

marine air wrote:I believe it was on there originally. I'm restoring an old Army jeep and sometimes the original stenciling is extremely thin. Also. if the camera wasn't focused on that area, and it would almost never be , then it simply wouldn't be picked up on film. Last, that is a "high wear" area prone to patching and redoping/ taping if they are operating off of gravel, mud , or anything other than hard asphalt.

While you bring up valid points, I respectfully disagree with regards to the L-5. With the amount of NOS parts I've seen (including a NOS wing in original fabric and paint), as well as the excellent photos taken of L-5s (especially those taken of L-5's being assembled out of the crate), I just can't imagine we are simply missing the cover codes. Not to mentioned the absence in the blueprints as mentioned above.

Just to reiterate, I have seen cover codes on depot refurbished parts, as seen below:

Once again, I would love to see proof to the contrary. Would be a game-changer in the life of this L-5 nerd and his future restorations!